UVC Emitters are ideal for hospitals, clinics, laboratories, hospices, senior facilities and medical offices.

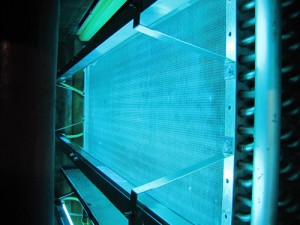

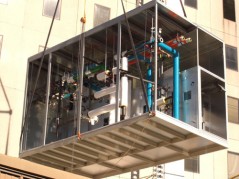

Steril-Aire UVC Installation

UV light in the form of germicidal lamps has been used since the late 1800s to kill the types of microorganisms that typically cause indoor air quality (IAQ) problems — bacteria, mold, yeast, and viruses.

Installed at the cooling coil and drain pan in an HVAC system, UVC eliminates surface biofilm — a complex matrix of mold, bacteria, viruses and debris.

Key Benefits to Health Care Facilities:

- Improved IAQ: Significantly decreases mold, bacteria and virus introduction to supply air stream. Reduced Hospital Acquired Infections (HAI) contributing to reduced hospital stays and reduced liability.

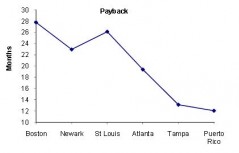

- Energy Savings: Lowers energy costs by improving HVAC system heat transfer and increasing net cooling capacity. Offers a return on investment in less than 2 years.

- Maintenance Savings: Continuously cleans coils, drain pans plenums and ducts, reducing or eliminating manual cleaning and the use of harmful chemicals.

- Water Conservation: Reclaiming clean condensate for tower makeup, irrigation or gray water flushing reduces water and waste water costs.

- LEED Contribution: UVC may contribute to LEED points in one or more areas.

From reducing energy consumption and controlling costs, to optimizing human and mechanical productivity, UVC solutions make real sense for Health Care Facilities.

“Our experiences have shown us repeatedly that UVC enhances indoor air quality and infection control, while saving on maintenance labor, materials and downtime. The substantial energy savings achieved have been a great bonus. Since our administrators now have a high confidence level in the effectiveness of UVC lights, we will continue to equip both new and existing air handling units with the devices.”

— Florida Hospital – Orlando, Florida

See related Blog Posts for more information on UVC Emitters:

Ask Rick: What is UVC?

Ask Rick: UVC Emitters | How will UVC provide cost savings?

Does Coil Cleaning Save Energy?

For manufacturer information see: Steril-Aire Healthcare Brochure

Steril-Aire Stakeholder Outreach Program

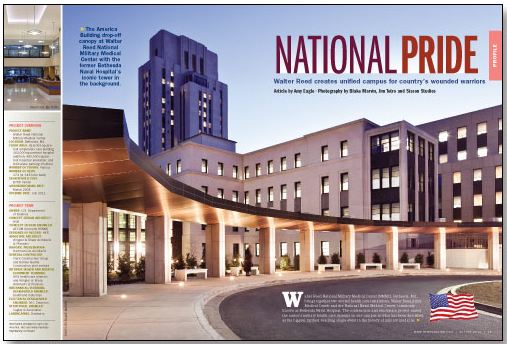

Eleven 16-foot diameter enthalpy wheels contribute to the natural ventilation in Walter Reed’s America and Arrowhead buildings. They play a substantial role in decreasing the hospital’s HVAC costs by 28 percent.

Eleven 16-foot diameter enthalpy wheels contribute to the natural ventilation in Walter Reed’s America and Arrowhead buildings. They play a substantial role in decreasing the hospital’s HVAC costs by 28 percent.

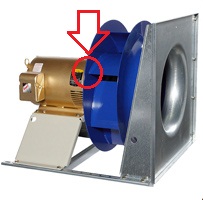

turbulence inside the AHU. This in turn reduces both velocity pressure (wasted energy) and noise. Pressurizing the plenum equally with low velocity air gives designers the flexibility to discharge in any direction they choose. You can’t do that with a scroll fan with the same simplicity as a plenum fan.

turbulence inside the AHU. This in turn reduces both velocity pressure (wasted energy) and noise. Pressurizing the plenum equally with low velocity air gives designers the flexibility to discharge in any direction they choose. You can’t do that with a scroll fan with the same simplicity as a plenum fan.

Project Scope:

Project Scope: Operational Data:

Operational Data: Design Parameters

Design Parameters