We have choices in equipment that we can select for air to air energy recovery applications, we even have the best options for Geothermal Heating and Air systems. Here are 5 advantages that Heat Pipes offer;

Energy Recovery Heat Pipes Features

Energy Recovery Heat Pipes Features

1. Passive Operation

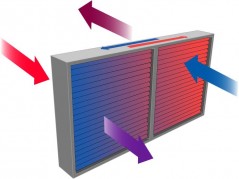

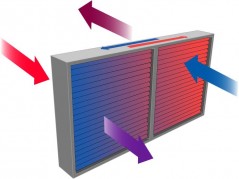

No energy input is required to operate the Heat Pipes. There are no moving parts. When two air streams pass through the Heat Pipes, one air stream on the supply side and the other on exhaust side, the temperature difference between the two air streams heats and cools refrigerant. The phase change of the refrigerant, from a liquid to a vapor and back again, transfers energy from one side to the other. It’s simple.

2. Long Life

There is nothing in the Heat Pipes to wear out! The Heat Pipes are passive. They have no moving parts. To guard against corrosion, the Heat Pipes can be ordered with a protective coating. The Heat Pipes are fabricated with a multitude of charged circuits. Under normal operations, there is no reason for these ever to leak. If one of the many circuits did leak there would be little impact on performance as other circuits would still function.

3. Isolated Air Streams

3. Isolated Air Streams

Dividing partitions to separate the two air streams can be easily added to Heat Recovery Heat Pipes. The copper tubes carrying the Heat Pipe working fluid are expanded into the mating holes in the dividing plates assuring an excellent seal to prevent cross contamination. This divider makes heat pipes a good choice in laboratory type applications, where cross contamination is a concern.

4. Minimum Maintenance

Since the Heat Pipes have no moving parts, the only maintenance recommended is periodic cleaning. A coil cleaner may be applied for this purpose just as for any cooling coil.

5. Flexible Size

Heat Recovery Heat Pipes from can take up less space than other heat recovery schemes. They can also be manufactured in custom sizes to fit nearly any application. Heat pipes can also be compact in depth. A six-row heat recovery heat pipe can be fabricated with a thickness of as little as 8 inches.

Further questions on heat pipes; askRick?

Related Blog Posts:

Heat Pipe for HVAC Systems | Heat Pipe Theory

Wrap Around Heat Pipe | How does a Wrap Around Heat Pipe work?

Visit Heat Pipe Technology for further information.

Does coil cleaning save energy? This was the first question that we asked before agreeing to promote

Does coil cleaning save energy? This was the first question that we asked before agreeing to promote

The study looked at a huge building in downtown NYC. See the following results and conclusions:

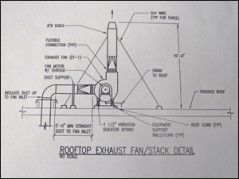

The study looked at a huge building in downtown NYC. See the following results and conclusions: Q. We are considering conversion of constant speed Strobic fans (six fans on a common mixing plenum) into variable speed fans by adding VFD’s to satisfy the the plenum static pressure set point. What do you recommend to ensure that we do not run them below the required minimum plume height.

Q. We are considering conversion of constant speed Strobic fans (six fans on a common mixing plenum) into variable speed fans by adding VFD’s to satisfy the the plenum static pressure set point. What do you recommend to ensure that we do not run them below the required minimum plume height.

Energy Recovery Heat Pipes Features

Energy Recovery Heat Pipes Features 3. Isolated Air Streams

3. Isolated Air Streams

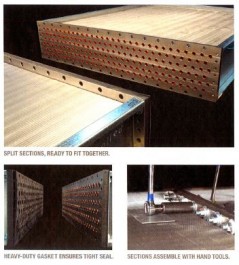

Split replacement coils offer a big advantage over having to create additional access space for coil replacements. It also allows us to design tighter units knowing this is available for future coil pulls.

Split replacement coils offer a big advantage over having to create additional access space for coil replacements. It also allows us to design tighter units knowing this is available for future coil pulls.