| Project Name: | Amherst College Science Center |

| Architect: | Payette Associates Inc. |

| Mechanical Engineer: | Van Zelm Engineers |

| Mechanical Contractor: | Harry Grodsky & Company |

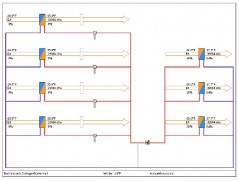

| Equipment: | Glycol Energy Recovery System with 20 AHU coils, 16 HRU Coils and Steam Humidifier |

| Manufacturer: | Konvekta |

| DAC Sales Engineer: | Rich Clarke |

Project Overview:

During the past 15 years, enrollment in STEM classes increased 85 percent and to meet this demand, Amherst College has built its new Science Center.

In Fall 2018, the school opened the four-story, 250,000-square-foot New Science Center with state-of-the-art teaching and research facilities. The center includes a science commons that unites the five wings of the building. It also includes classrooms, teaching labs, a library, café and informal learning areas for students. In addition to the new building, improvements were made to the infrastructure that serves the building as well as the Greenway Dorms. These upgrades include chilled beams in all laboratory spaces, radiant ceiling panels in offices and classrooms, displacement ventilation in all non-lab areas, radiant heating/cooling floor system in the atrium area, a high efficiency glycol run-around system, daylight dimming capability in all areas with natural light, and a storm water recycling system.

In Fall 2018, the school opened the four-story, 250,000-square-foot New Science Center with state-of-the-art teaching and research facilities. The center includes a science commons that unites the five wings of the building. It also includes classrooms, teaching labs, a library, café and informal learning areas for students. In addition to the new building, improvements were made to the infrastructure that serves the building as well as the Greenway Dorms. These upgrades include chilled beams in all laboratory spaces, radiant ceiling panels in offices and classrooms, displacement ventilation in all non-lab areas, radiant heating/cooling floor system in the atrium area, a high efficiency glycol run-around system, daylight dimming capability in all areas with natural light, and a storm water recycling system.

Learn more about the Science Center

Designed with Sustainability in Mind

Amherst gathered a world-class team of industry leaders to design a new type of science building. Leveraging new technologies, our team of architects, engineers and sustainability experts developed sophisticated solutions, using computational modeling to explore various options and refine the designs. Their resulting innovations set the stage for the Science Center to perform at an unparalleled level of energy efficiency. The average science building uses about 370 kiloBTUs per square foot per year. We intend to reduce that by 73 percent or more through a variety of features: highly efficient systems for everything from the building HVAC down to individual lab hoods; a state-of-the-art insulating building envelope; and careful floor plan design so that sensitive and specialized lab systems are grouped together.

Konvekta: Unique Cost Transparency Concerning Energy Efficiency

The HVAC system at the Amherst College Science Center was supplied by Konvekta and incorporates their glycol heat recovery units

Konvekta AG, founded in 1949, is one of the leading manufacturers of air/liquid lamellar heat exchangers. The heat exchangers are custom designed for each application and manufactured in Switzerland. They are primarily suitable for utilization in HVAC energy recovery.

The Konvekta system is based on three core elements of a high-efficiency energy recovery system at their disposal:

• Highly efficient heat exchanger

• Hydraulic assembly unit

• System Controller – After installation of a Konvekta heat recovery system, the system controller continuously records the system operating parameters and transmits the data via the internet to Konvekta headquarters in Switzerland. The Syskom software calculates the investment cost as well as the annual operating cost of entire HVAC systems (air-conditioning system, refrigeration plant including re-cooling). Depending on the customer’s interests, the system can be optimized through changes in operating conditions and variations of components. This computing service is free of charge for Konvekta customers.

Konvekta Energy Recovery Coil

Related Blog Posts:

UVM Stem Complex

University Biology Lab HVAC Upgrade

Pumped Glycol Energy Recovery | Efficiency vs. Effectiveness

Leave a Reply