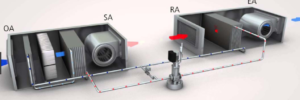

Project Name: Alkermes Architect: Elkus Manfredi Archtects Mechanical Engineer: AHA Consulting Engineers Mechanical Contractor: Hamel & McAlister Equipment: (2) Custom Penthouse AHUs, (2) EAHUs, (1) Konvekta Heat Recovery Skid (6) MK Plastics High Plume Dilution Fans, (2) 450 ton Oil-Free Chillers, (21) Carel HeaterSteam Humidifiers Manufacturer: Konvekta, Cambridgeport, MK Plastics, Smardt, Ingenia Carel Size: 140,000 CFM… Read more »