Thermotech Wheel With Purge

There are two ways that air can leak from the exhaust side to the supply side of a wheel:

Cross-Flow Leakage – occurs when air leaks from the exhaust side to the supply side through the seals or any gaps in the construction.

Carryover Leakage – occurs in rotary recovery wheels as the wheel rotates from the exhaust to supply air stream. A small amount of exhaust air can be carried over in the flutes of the wheel as it passes by the center-line seal.

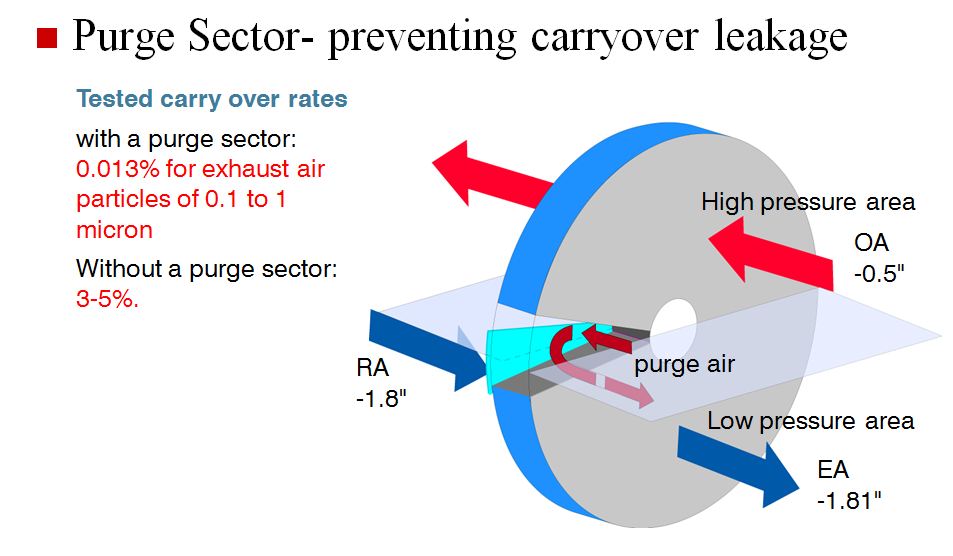

Cross-contamination can be virtually eliminated by a “Purge Section”, which is an integral part of the casing design. The purge section utilizes the pressure difference which exists between the outdoor and return air streams to “purge” the transfer media with clean outdoor air prior to its rotation into the supply air stream. The figure below provides a graphic representation of the purge section operation.

The purge section is adjustable. This allows for optimizing the required purge volume during system start-up, regardless of the pressure difference between the outdoor and return air streams (provided that the return air pressure is lower than that of the outdoor air).

Be advised, an energy recovery wheel purge section is a feature that will reduce carryover leakage. It will not guarantee zero leakage from the exhaust side to the supply side of the unit. Energy Recovery Wheels | Understanding Cross Contamination / Leakage

Also, do not use a purge section on every unit. If you are not concerned with carryover then don’t use a purge (like in a typical school application). The purge comes with an energy penalty. Air flows are typically increased from 5 to 7% on both the supply and exhaust side to feed the purge.

Related Blog Posts:

Energy Recovery Wheels | What is an Enthalpy Wheel?

Ask Rick: Energy Recovery Wheels on Laboratory Fume Hood Exhaust?

Ask Rick: How much cross contamination occurs with an Energy Recovery Wheel?

Leave a Reply