| Project Name: | University of New Hampshire Parsons Hall Renovation |

| Architect: | Einhorn Yaffee Prescott |

| Mechanical Engineer: | Einhorn Yaffee Prescott |

| Contractor: | Gilbane Building Company |

| Equipment: | High Plume Dilution Fan – Energy Recovery Systems |

| Manufacturer: | Strobic Air / Cambridgeport Air Systems |

| Size: | 5 Ea. Energy Recovery Units – sized from 20,000 CFM to 48,000 CFM |

| DAC Sales Contact: | Jim Shiminski |

Project Overview:

The University of New Hampshire (UNH) was looking to renovate Parsons Hall, which housed the Chemistry Department and a few related programs. The renovated facility was designed to accommodate wet teaching laboratories, research labs, the University Instrumentation Center and general classroom space. It was also to include office space for faculty, researchers, technicians, postdoctoral fellows, and student researchers, as well as common spaces such as a conference rooms and break-out spaces.

The University of New Hampshire (UNH) was looking to renovate Parsons Hall, which housed the Chemistry Department and a few related programs. The renovated facility was designed to accommodate wet teaching laboratories, research labs, the University Instrumentation Center and general classroom space. It was also to include office space for faculty, researchers, technicians, postdoctoral fellows, and student researchers, as well as common spaces such as a conference rooms and break-out spaces.

Project Challenges:

- The renovation schedule for the project included work that was to commence after the UNH graduation in May 2009 and last through 2014. All equipment was to be prepurchased by Gilbane and coordinated through the life of the project.

- Energy Savings was key to the project. All HVAC systems needed to provide optimal energy savings.

- The fans needed to get lab exhaust up and away from the building. The exhaust systems were located on the edge of common courtyard area. Prior fans contributed a great deal of noise to the area. Sound attenuation was a critical aspect of the design.

- The fan systems would be visible from several points on the campus. They needed to be low profile and compact.

Project Highlights:

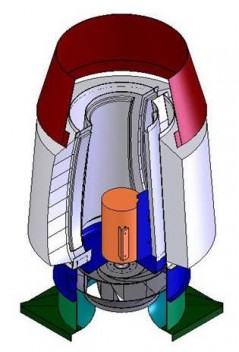

High Plume Dilution Fans from Strobic Air were selected for the project. Five separate Pumped Glycol Energy Recovery Exhaust Units were designed. Four of the units had two and one unit had three Strobic Air Tri-Stack Fans. Each unit had a pumped glycol energy recovery coil (for energy savings) and a filter bank. Fans were designed to run on VFDs to optimize fan horsepower. Fans were also designed to stage off to match building load.

Integral Nozzle Silencer from Strobic Air

Integral Nozzle Silencers were included with the Strobic Lab Exhaust Fans for sound attenuation. The sound data for the Tri-Stack Fan and nozzle silencers, tested as a complete package, met or exceeded all site sound criteria.

All Pumped Glycol Energy Recovery Units were designed to be compact and low profile. Integral Silencers Reduced fan system height. Energy Recovery Plenum Sections, provided by Cambridgeport Air Systems, supported the fan systems. Plenum sections were built with All Aluminum Construction to provide the most sustainable long term solution. Cost was comparable to painted steel construction and weight savings was about 40%.

See plan highlights on the UNH Project website: Parsons Hall Renovation

If you have questions about the application, feel free to askRick?

Related Blog Posts:

High Plume Dilution Fans | What is a High Plume Dilution Fan?

High Plume Dilution Fans | 3 Key Design Questions

High Plume Dilution Fans | Online Selection For Lab Exhaust Fans

Leave a Reply