The new 220,000 square foot Integrated Science Complex at the University of Massachusetts – Boston Campus will be the first new academic building on the campus since it opened in 1974. The building is expected to achieve LEED Silver certification and will open in 2014. A state of the art Konvekta energy recovery system is being installed as a key part of the energy efficiency plan.

The new 220,000 square foot Integrated Science Complex at the University of Massachusetts – Boston Campus will be the first new academic building on the campus since it opened in 1974. The building is expected to achieve LEED Silver certification and will open in 2014. A state of the art Konvekta energy recovery system is being installed as a key part of the energy efficiency plan.

| Project Name: | UMass Boston – Integrated Science Complex |

| Architect: | Goody Clancy |

| Mechanical Engineer: | Vanderweil |

| Contractor: | J. C. Higgins |

| Equipment: | High Efficiency Pumped Glycol Energy Recovery Systems |

| Manufacturer: | Konvekta |

| Size: | 210,000 CFM total |

| DAC Sales Contact: | DAC Sales |

Technology

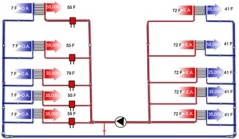

The Konvekta energy recovery system serves five supply air handling units and two exhaust air handling units. In addition to energy recovery the system provides all heating of the 210,000 CFM of supply air. On cold winter days this is achieved with the help of plate and frame heat exchangers that boost the water/glycol temperature. The plate and frame heat exchangers are fed with hot water from the boiler.

The Konvekta energy recovery system serves five supply air handling units and two exhaust air handling units. In addition to energy recovery the system provides all heating of the 210,000 CFM of supply air. On cold winter days this is achieved with the help of plate and frame heat exchangers that boost the water/glycol temperature. The plate and frame heat exchangers are fed with hot water from the boiler.

Operating Performance

During the winter season the Konvekta system with provide nearly 80% of the net heating requirement for the building from energy recovery.

Konvekta: Unique Cost Transparency Concerning Energy Efficiency

Konvekta AG, founded in 1949, is one of the leading manufacturers of air/liquid lamellar heat exchangers. The heat exchangers are custom designed for each application and manufactured in Switzerland. They are primarily suitable for utilization in HVAC energy recovery.

The Konvekta system is based on three core elements of a high-efficiency energy recovery system at their disposal:

The Konvekta system is based on three core elements of a high-efficiency energy recovery system at their disposal:

• Highly efficient heat exchanger

• Hydraulic assembly unit

• System Controller – After installation of a Konvekta heat recovery system the system controller continuously records the system operating parameters and transmits the data via the internet to Konvekta headquarters in Switzerland. The Syskom software calculates the investment cost as well as the annual operating cost of entire HVAC systems (air-conditioning system, refrigeration plant including re-cooling). Depending on the customer’s interests, the system can be optimized through changes in operating conditions and variations of components. This computing service is free of charge for Konvekta customers.

Related Blog Posts:

Pumped Glycol Energy Recovery | What’s so special about Konvekta?

Pumped Glycol Energy Recovery | Preliminary Design Questions

Leave a Reply