| Project Name: | East Boston Stadium HVAC Improvements |

| Engineer: | Engineered Systems, Inc. |

| Contractor: | P.J. Kennedy and Sons |

| Equipment: | Passive Heat Pipe Energy Recovery Module |

| Manufacturer: | Heat Pipe Technology |

| DAC Sales Engineer: | David Goodman |

Project Highlights:

Existing Conditions: Football is a proud tradition in East Boston and funding was raised to replace original and antiquated HVAC equipment in the Stadium. 6800 CFM was going to be required to meet ventilation rates for the offices, locker rooms, showers and other spaces. A boiler upgrade was also part of the project. The mechanical space had a small man entry and an awkward shape. A floor cut of the concrete was agreed on and the engineer tried to select a Packaged Energy Recovery Unit that would fit. The floor access could not be cut large enough to rig a packaged unit and a custom field erect unit was not in the budget.

Existing Conditions: Football is a proud tradition in East Boston and funding was raised to replace original and antiquated HVAC equipment in the Stadium. 6800 CFM was going to be required to meet ventilation rates for the offices, locker rooms, showers and other spaces. A boiler upgrade was also part of the project. The mechanical space had a small man entry and an awkward shape. A floor cut of the concrete was agreed on and the engineer tried to select a Packaged Energy Recovery Unit that would fit. The floor access could not be cut large enough to rig a packaged unit and a custom field erect unit was not in the budget.

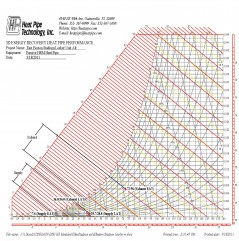

The Solution: Engineered Systems, Inc. (ESI) selected a supply and exhaust fan to move the required air. David Goodman from DAC Sales sized and selected a passive Heat Pipe Energy Recovery Module and 5 Hot Water reheat coils, the largest to be located after the Heat Pipe in the mechanical space. The Heat Pipe selected was 120”L X 40”H – 6 Row – 12 FPI. The Heat Pipe, Hot Water Coil and filters were connected to the fans with simple ducting connections. All these parts were chain fall lifted through the new access hole and field assembled according to the plans.

The Solution: Engineered Systems, Inc. (ESI) selected a supply and exhaust fan to move the required air. David Goodman from DAC Sales sized and selected a passive Heat Pipe Energy Recovery Module and 5 Hot Water reheat coils, the largest to be located after the Heat Pipe in the mechanical space. The Heat Pipe selected was 120”L X 40”H – 6 Row – 12 FPI. The Heat Pipe, Hot Water Coil and filters were connected to the fans with simple ducting connections. All these parts were chain fall lifted through the new access hole and field assembled according to the plans.

The Results: The Heat Pipe greatly reduced the new boiler sizing and energy consumption. 283,000Btu’s/hr. were saved at design conditions. A by-pass damper was also included to provide frost protection on very cold days.

More questions on Heat Pipe systems; askRick?

Related Energy Recovery Blog Posts:

Energy Recovery Heat Pipes | Frost Control for Heat Pipe Applications

Ventilation Energy Recovery | 5 Key Questions to Ask to Determine Air-to-Air Energy Recovery Device

Leave a Reply