Topic: Energy-Efficient Makeup Air Units

Guest Blogger: Hugh Crowther, P.ENG., Ashrae Member

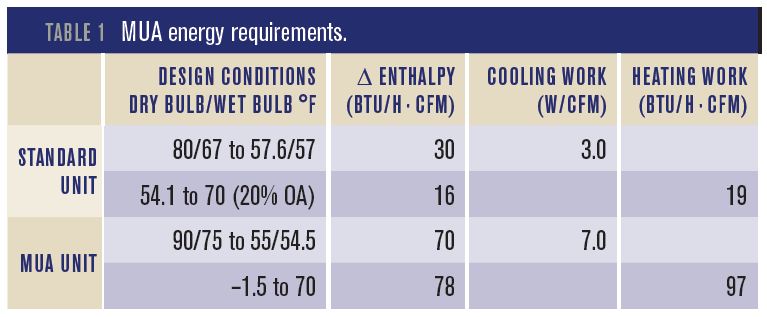

Unless you live in paradise, delivering makeup air to most buildings is expensive. Table 1 shows the amount of work it takes to heat and cool air (based on Chicago conditions) for a standard rooftop unit (a unit that recirculates air with typical air conditioning loads) and a makeup air (MUA) unit. Note the standard unit conditions represent 400 cfm/ton (53.68 L/[s·kW]) with 80°F dry bulb/67°F wet bulb (26.7°C dry bulb/19.4°C wet bulb) return air conditions. It can be seen that a MUA unit requires more than twice the cooling and five times the heating work as a standard unit.

For many HVAC solutions a dedicated outdoor air system (DOAS) is required such as variable refrigerant flow systems (VRF), ground source heat pumps (GSHP), and chilled beams (Figure 1).

Many process applications (labs, industrial processes, garages, etc.) also require makeup air (MUA) systems. All these applications require some form of make up air unit that can move and filter outdoor air as well as heat and cool (depending on location and application). Since these units consume significant energy in most applications, a discussion on how to improve their efficiency is warranted.

A basic MUA unit has to meet certain minimum performance requirements:

• 80% efficient (indirect fired) gas heat1 (assuming a gas heat unit);

• 10 EER (Energy Efficiency Ratio)2 if DX cooling is required;

• Fan performance is generally marginalized but is accounted in the unit EER requirement (assuming there is cooling); and

• Basic wall construction called out in the product specification. A basic unit is typically single wall, 0.5 to 1 in. (13 to 25 mm) fiberglass insulation. To move beyond a basic unit, four areas of improvement will be considered: gas heat, DX cooling, fan performance, and casing performance (Figure 2). The energy usage calculations are based on a 10,000 cfm (4700 L/s) MUA unit in Chicago. The cost3 of gas is $0.79/therm and electricity is $0.10 kWh. The carbon dioxide (CO2)

equivalent conversion4 for natural gas is 0.510 CO2e lb/kWh (0.232 kg/kWh) and for electricity is 1.670 CO2e lb/kWh (0.758 kg/kWh). Calculations are based on 24/7 operation.

See remainder of article at: Energy-Efficient Makeup Air Units

Leave a Reply