Konvekta is the only supplier of high efficiency pumped glycol run-around energy recovery systems in the world. They have been in the business of pumped glycol energy recovery since 1949. That’s all they do. Konvekta offers complete systems – high performance heat exchangers, energy recovery system controls and hydraulic assembly.

Konvekta is the only supplier of high efficiency pumped glycol run-around energy recovery systems in the world. They have been in the business of pumped glycol energy recovery since 1949. That’s all they do. Konvekta offers complete systems – high performance heat exchangers, energy recovery system controls and hydraulic assembly.

Konvekta high-performance energy recovery systems reduce energy consumption by 70-90%.

Konvekta guarantees system performance and provides monitoring and reporting that proves that the guaranteed energy savings are met.

Konvekta – Auto Reporting Plus – Continuous monitoring with watchdog capabilities

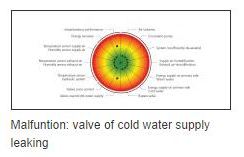

System malfunctions or reduced performance are detected and can be quickly resolved. This guarantees system availability and maximum recovery.

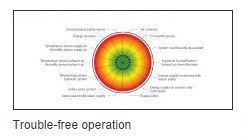

The goal of each energy recovery system is optimal net annual energy recovery which yields the greatest energy cost savings over lifetime of the building. This requires optimized and malfunction-free operation. Installation error, software glitches and erroneous set values must be detected.

Comprehensive information at a glance

The increased use of electronics and software makes systems more complex. Therefore, it is important that system operators continuously receive easy-to-interpret information about operating status and potential problems. With the new Auto-Reporting Plus all critical data is monitored and displayed visually. Data is also displayed graphically over the internet and is password protected to ensure security. Thanks to the clear, visual presentation of data, all important operating parameters can be easily assessed to ensure recovery efficiency and optimal system operation so that performance goals are achieved.

The increased use of electronics and software makes systems more complex. Therefore, it is important that system operators continuously receive easy-to-interpret information about operating status and potential problems. With the new Auto-Reporting Plus all critical data is monitored and displayed visually. Data is also displayed graphically over the internet and is password protected to ensure security. Thanks to the clear, visual presentation of data, all important operating parameters can be easily assessed to ensure recovery efficiency and optimal system operation so that performance goals are achieved.

Performance monitoring

Energy recovery systems that are not monitored are installed, started-up and just left to run year after year without analyzing performance. This results in system malfunctions not being noticed. Thanks to the continuous set value/actual value comparison critical system data is monitored and performance deviations are noticed immediately by Auto-Reporting Plus. When a system malfunction is detected an automatic error message notifies system operators immediately through the building automation system. At the same time the system controller analyzes the error.

The benefits of Auto-Reporting Plus

- Comprehensive information at a glance tells you if the system is optimized, functioning trouble-free, and achieving the guaranteed performance

- Continuous automatic monitoring function

- Automatic error detection, including functions upstream and downstream of the energy recovery system such as primary power or the function of the supply air or exhaust air humidification

- Downtime is minimized thanks to the automatic analysis of errors – resulting in maximum energy cost savings

- Rapid response time to errors thanks to prompt notification

What’s so special about Konvekta?

- Konvekta specializes in pumped glycol energy recovery systems. That’s all they do.

- They are based in Switzerland and have been in business for over 60 years, doing only pumped glycol energy recovery systems.

- Last year their sales were over $60 million.

- Konvekta supplies the entire package. They make their own coils, pump packages and controls.

- The reason they are so successful is they are able to achieve 65-75% effectiveness with glycol loop systems and they guarantee the savings. That’s right, they guarantee the savings.

- The Konvekta system is the only pumped glycol energy recovery system that will meet the new minimum efficiencies in the revised ASHRAE code.

Related Project Snapshots:

Project Snapshot | Dartmouth College – Konvekta System

Project Snapshot | UMass Boston – Integrated Science Complex

Project Snapshot | Hudson Valley CC – Konvekta System

Leave a Reply