| Project Name: | John Hannigan Elementary School |

| Architect: | Turowski2 Architecture, Inc. |

| Mechanical Engineer: | Griffith and Vary |

| Mechanical Contractor: | KMD Mechanical |

| Equipment: | 5 Rooftop Units with DX |

| Manufacturer: | Annexair |

| Size: | 6,050, 7,285, 10,200, 4,000, and 6,100 CFM |

| DAC Sales Engineer: | Pat Will |

Project Overview:

The students in the northern part of the South End peninsula are now walking through the doors of the brand new 74,000 square foot John Hannigan Elementary School which, unlike the one built in 1919, has a state-of-the-art cafeteria, gymnasium, and an art and music classroom. Children at Hannigan had been attending the Sea Lab on Portland Street since 2006 when the roof collapsed at the old Hannigan. The original Hannigan school was demolished and rebuilt with modern features that now serves 400 elementary students and houses the Family Learning Center, classroom sizes of 20 students for lower grades and 26 per class for higher grades and two pre-K classes.

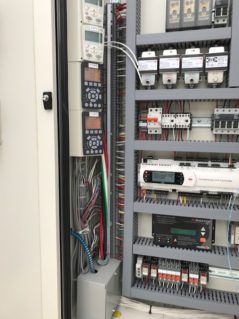

HVAC Highlights:

- Hot Water Coils

- DX Coils

- Enthalpy Wheels

- Thermo-composite panel system

The units at the John Hannigan Elementary School were supplied by Annexair and incorporated their Thermo-composite panel system. The design looked for replacement units that would weigh the same as original and provide 30% more capacity. Weight was a key design factor. The Annexair units are 30% lighter than traditional steel units. So we were able to satisfy the design criteria with a lighter unit. Additionally the units come with a lifetime warranty against corrosion. Best of all they are the same cost as traditional steel units.

Take a look at the specification for key features:

UNIT HOUSING SPECIFICATION (Thermo-composite) The unit housing shall be no-through metal with 2’’ Thermo-Composite and foam panel construction – interior and exterior. No-through metal construction will be inherent to all the component construction in the assembly. All panels and access doors shall be double wall construction with R14 foam insulation for every 2” of construction. All foam insulation must be Greenguard certified®. Unit casing will have no exterior condensation at interior AHU temperatures down to 43F while unit exterior conditions are maintained at 95 F dry bulb / 85 F wet bulb. The panels shall be tested in accordance with SMACNA and ASHRAE 111 to have a deflection of no more than L/1150 at 10’’ and withstand air pressures up to 8” w.c with less than 1% leakage. Fire resistance of the panel will be in compliance with UL 94.

Thermo-Composite panels with aluminum interior and exterior liners shall be provided for the entire unit construction, including but not limited to, walls, doors, floors, roof, interior partitions, and electrical compartment. The frame shall consist of anodized extruded aluminum profiles which incorporates a thermally broken construction; welded together for reinforcement and insulated for superior thermal performance. Base structure shall be fully welded and have integral lifting lugs which can be removed once the unit is installed. All roof and side wall seams shall be positively sealed to prevent water and air leakage. Panels will be non-load bearing type. Access doors shall be provided to all major components to facilitate quick and easy access. They shall be made from the same material as the unit casing and incorporate thermal break construction. Access doors shall be provided with open door guard locks shall have Allegis type latches. If access doors do not open against unit operating pressure, provide safety latches that allow access doors to partially open after first handle movement and fully open after second handle movement. Removable panels provided for equipment pull out for coil(s) sections shall have key tooled threaded insert fasteners and a minimum of one handle. Hinges shall be Nylon hinge type designed to open 180 degrees.

Outdoor units shall have a rain gutter above each access door and a watertight roof shall be provided with a white TPO UV-reflective membrane. Unit shall have the entire exterior finished with a PVDF coating designed for UV resistance. Panels shall be painted Annexair standard color. Panels shall pass ASTM B117 3000-hour salt fog resistance test and ASTM D4585 3000-hour moisture condensation resistance test. In addition, paint must meet AAMA 620-02 standard for color, chalking, gloss retention, and abrasion resistance. The air handler unit casing shall be provided with a lifetime warranty against corrosion resistance under normal use.

white TPO UV-reflective membrane. Unit shall have the entire exterior finished with a PVDF coating designed for UV resistance. Panels shall be painted Annexair standard color. Panels shall pass ASTM B117 3000-hour salt fog resistance test and ASTM D4585 3000-hour moisture condensation resistance test. In addition, paint must meet AAMA 620-02 standard for color, chalking, gloss retention, and abrasion resistance. The air handler unit casing shall be provided with a lifetime warranty against corrosion resistance under normal use.

Related Thermo-composite Panel Blog Posts:

Project Snapshot: Ayer-Shirley High School | Thermo Composite-DOAS Units

Project Snapshot: Subaru of New England | Thermo Composite AHUs

Project Snapshot: 27 Melcher Street | Themo Composite AHUs

5 Reasons to Consider a Composite Air Handling Unit

Leave a Reply