Project Overview:

1030 Massachusetts Avenue is located in Harvard Square and within walking distance to Central Square. The building is a former office building developed in the mid-1980’s. It was acquired by Longfellow Real Estate Partners and its partner in November 2009.

After acquisition, Longfellow vacated all of the office tenants in the building and redeveloped the shell and core to Class A lab standards. In addition, Longfellow oversaw the design and construction of two 10,000 RSF speculative labs to meet the time and planning constraints of some new users. The building offers tenants proximity to Harvard, MIT and the surrounding science cluster as well as the unrivaled convenience of restaurants, shopping, entertainment and access to public transportation.

| Project Name: | 1030 Mass. Ave. – Cambridge, MA |

| Mechanical Engineer: | AHA Consulting Engineers |

| General Contractor: | The Richmond Group |

| Mechanical Contractor: | Cannistraro |

| Equipment: | High Plume Dilution Fan – Energy Recovery Systems |

| Manufacturer: | Strobic Air / Cambridgeport Air Systems |

| Size: | Energy Recovery Unit – sized 56,000 CFM |

| DAC Sales Contact: | Jim Shiminski |

Project Challenges:

Project Challenges:

- The exhaust fans needed to get lab exhaust up and away from the building. The exhaust system was to be located on the back side of the building. Sound attenuation was a critical aspect of the design.

- Energy Savings was key to the project. All HVAC systems needed to provide optimal energy savings.

- The fan system could possibly be visible from several points in the neighborhood. The system needed to be low profile and compact.

Project Highlights:

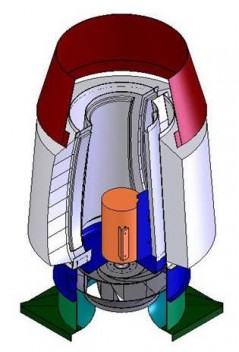

High Plume Dilution Fans from Strobic Air were selected for the project. They were mounted on a Pumped Glycol Energy Recovery Exhaust Unit specifically designed for the application (see picture above). The unit was complete with a pumped glycol energy recovery coil (for energy savings) and a filter bank. Fans were designed to run on VFDs to optimize fan horsepower. Fans were also designed to stage off to match building load.

Integral Nozzle Silencer from Strobic Air

Integral Nozzle Silencers were included with the Strobic Lab Exhaust Fans for sound attenuation. The sound data for the Tri-Stack Fan and nozzle silencers, tested as a complete package, met or exceeded all site sound criteria.

The Pumped Glycol Energy Recovery Unit was designed to be compact and low profile. Integral Silencers Reduced fan system height. Energy Recovery Plenum Sections, provided by Cambridgeport Air Systems, supported the fan system.

A Smart Fan Control system, by Strobic Air, was included in the application. The system provided complete controls to manage all variable flows. Signals from the Smart Fan Controller were sent to VFDs, Bypass dampers and Isolation Dampers to manage for optimum system flow and energy use. Inclusion of the system provided significant motor horsepower savings.

A Smart Fan Control system, by Strobic Air, was included in the application. The system provided complete controls to manage all variable flows. Signals from the Smart Fan Controller were sent to VFDs, Bypass dampers and Isolation Dampers to manage for optimum system flow and energy use. Inclusion of the system provided significant motor horsepower savings.

If you have questions about the application, feel free to ask us.

Related Blog Posts:

High Plume Dilution Fans | What is a High Plume Dilution Fan?

High Plume Dilution Fans | 3 Key Design Questions

High Plume Dilution Fans | Introducing the Strobic Air Smart Fan Control System

Leave a Reply