Preliminary Design Questions for a Pumped Glycol Energy Recovery System:

Dartmouth Burke Hall - Konvekta System

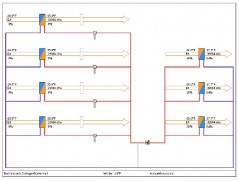

Every energy recovery design starts with a list of questions that should be answered. If these items are explored and discussed early on it makes for a significantly better design. There are several distinct advantages in packaged pumped glycol systems from Konvekta. A key system aspect is that you can take energy from multiple exhaust units and distribute it to multiple supply units. This is a big part of what makes the system so efficient; you take the energy from where it is and transfer it to where it is needed.

Here are the key items that we look for in preliminary design of a Pumped Glycol Energy Recovery System:

- Project Name:

- Project Location:

- Supply Air

- AHU Qty:

- CFM/ AHU:

- Outside Air Percentage:

- Coil bank size – dimensions if possible, Face Velocity at minimum (500, 400 FPM):

- Desired LAT – DB/WB – Summer & Winter:

- If providing full heating through energy recovery coil: Heat source – Hot water or steam, Temperatures available

- Exhaust Air

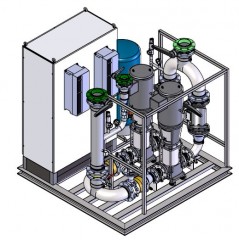

Konvekta Pumping Skid

- EAHU Qty:

- CFM/ EAHU:

- Coil bank size – dimensions if possible, Face Velocity at minimum (500, 400 FPM)

- Exhaust Air Temperatures – DB/WB:

- Exhaust quality – What is being exhausted? Would the coils need a coating?

- Adiabatic Cooling – would this be an option

- General Data

- Schedule of occupancy – night setbacks, partial occupancy, summer shutdowns, etc.

- Utility Rates – average $/KWh, $/BTU heating, etc

- Glycol – Ethylene or propylene

The more complete the information, the better the analysis. In this preliminary phase we like to come up with a payback analysis for the project. That’s always a starting point with any energy recovery application.

See related Blog Posts on Konvekta:

Pumped Glycol Energy Recovery | What’s so special about Konvekta?

Pumped Glycol Energy Recovery | Konvekta High Performance Heat Exchanger Coil

Ask Rick: Pumped glycol energy recovery systems | Reasons for poor performance in traditional systems

Leave a Reply