Introduction:

Many buildings require substantial amounts of outside air to be brought in through their ventilation systems. In many cases it is code ( schools) and in other cases it constitutes make up air for contaminated exhaust air (laboratories). Regardless, exhausting expensive conditioned indoor air and replacing it with outdoor air is really expensive. Energy recovery devises, like the Enthalpy Wheel, can be incorporated in the design to transfer outgoing temperature and humidity (energy) to the incoming outdoor air.

Application:

Most energy recovery devices transfer heat (sensible) energy only. An Enthalpy Wheel allows both heat (sensible) energy and moisture (latent) energy to be exchanged. The Enthalpy Wheels are usually made of porous materials to increase surface area which aids in energy transfer. In most cases a matrix core material is coated with a desiccant such as Silica Gel or other molecular sieves to increase latent transfer.

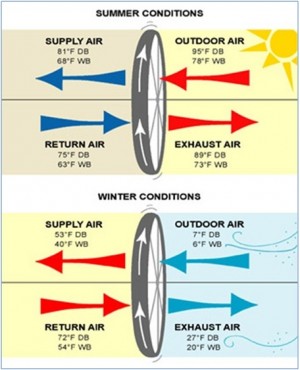

The Enthalpy Wheel, coated with a desiccant material, is rotated between the incoming fresh air and the exhaust air. Heat and moisture are given up to the wheel. When the space is in the heating mode, the heat and desirable humidity is used to pre-condition the incoming, cold, dry air. In the cooling mode, the incoming air is pre-cooled and dehumidified.

Because the cost to remove moisture can represent 30 to 50% of the cost to condition air, substantial additional savings are available with enthalpy wheels over conventional air-to-air exchangers. This is something that every home owner should keep in mind, when deciding to get air conditioning services.

Typical of energy exchanged through an enthalpy wheel.

For further detail on Enthalpy Wheels visit Thermotech.

Leave a Reply