Nearly once a week I am confronted with this question. My customer, “I have an application for Air-To-Air energy recovery. What type of energy recovery device should I use?” My answer is nearly always the same, “That depends”.

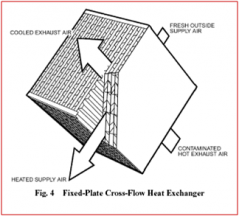

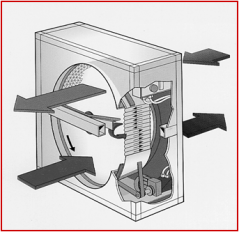

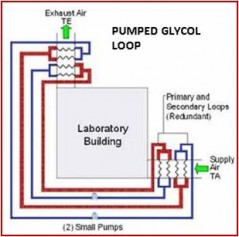

We have several choices. All the technology has been around for long time now. Pumped glycol loops were invented and used as long ago as 1949 by Konvekta, in Switzerland. The first commercial wheel was created in 1954 by Anders Munters. Heat pipes were invented in 1963 at Los Alamos National Laboratory (they are rocket science). Nick Des Champs commercialized plate Air-To-Air heat exchangers during the energy crisis of 1974. Each technology has evolved over time and all have been extensively used in our HVAC industry.

When we look to determine the best fit for the application we start with five key questions.

These are key factors that we consider when choosing the type of energy recovery device:

- Can supply air and exhaust air be run side by side? If no, rule out everything but the glycol run around loop. The glycol run around loop is the most effective device to use in applications where supply and exhaust air streams cannot be brought next to each other.

- What is in the exhaust air stream? There is a big difference between a laboratory and elementary school application (not just the size of the kids). If there is something dangerous in the exhaust air stream most building owners will still shy away from enthalpy wheels. There is a concern about cross contamination from the exhaust to the supply side on the wheel. The best energy recovery choices for contaminated air streams have been either heat pipes (which can be sealed from one side to the other) or run around glycol loops.

If exhaust air is clean then we would typically use the most effective device; the energy recovery wheel. - Is summer energy recovery required? The energy recovery wheel is the most effective device (typically 70 to 80% effectiveness). That is because this device is the only true enthalpy (water) transfer device. If the application runs in the summer we typically use a wheel, especially in humid applications.

- Are there any size constraints? In most typical applications the size of the energy recovery device determines the size of the Energy Recovery Unit. If space is an issue then we typically favor heat pipes and glycol run around loops. These devices can be dimensionally changed to fit a lot of different applications.

- Are there any maintenance concerns? If there are considerable concerns about maintenance then we favor passive devices, like heat pipes and plate exchangers. Poor quality wheels can be a maintenance nightmare. Pumped glycol loops have to be maintained also.

This is just a start to the process. These are five of the key things to consider when choosing an air-to-air energy recovery device. See links to learn more specific information about each technology.

Q. When are Tilt Mechanisms used on Heat Pipes?

Q. When are Tilt Mechanisms used on Heat Pipes? Overcoming Space Constraints: This was one of the final exhaust fan installations on the Blackfan Building in downtown Boston. There was very little room to place the fan system on the building. The

Overcoming Space Constraints: This was one of the final exhaust fan installations on the Blackfan Building in downtown Boston. There was very little room to place the fan system on the building. The

Q. The Smart Fan brochure says ”Communicates with most building systems” (p. 1) – please elaborate. We have an existing Johnson DDC system here.

Q. The Smart Fan brochure says ”Communicates with most building systems” (p. 1) – please elaborate. We have an existing Johnson DDC system here.