We have worked with Variable Air Volume (VAV) Diffusers from Acutherm for 20 years now (they have been around since 1978). In the start there was one option; a stand alone Thermally Powered VAV Diffuser. It was called the Therma-Fuser. That was it and it worked very well. Today we have choices.

There are at least six ways to design a system and a fairly wide range of Building Automation System (BAS) options available. Whether you’re looking for simple individual temperature control, requiring no energy for operation, or a full-scale networked system, it’s available now. Here’s a brief overview of the six basic options.

Acutherm Therma-Fuser

Option 1: Therma-Fuser™ stand alone diffusers

This is as simple as it gets. This configuration provides the comfort and energy savings of individual temperature control at the lowest cost available. Low cost and low maintenance makes it a long time favorite. In this case the BAS is simply controlling supply air temperatures to the VAV Diffusers.

Option 2: Therma-Fuser™ stand alone diffusers with Room Temperature Sensors

Same as above and also monitoring room air temperatures with the BAS. The BAS can read an analog room temperature signal from a sensor installed in each diffuser. In this case the BAS is simply monitoring the system and controlling air temperatures.

Acutherm Digital Wall Adjusters

Option 3: Therma-Fuser™ stand alone diffusers with Wall Adjusters

Adjust room temperature set point with the BAS.

The BAS can read and reset the room temperature setpoint of each diffuser using analog signals from an Acutherm Wall Adjuster. The Wall Adjuster may be installed on the diffuser or on the wall and may be either wireless or wired to the diffuser.

Option 4: Therma-Fuser™ stand alone diffusers with Room Temperature Sensors and Wall Adjusters

A combination of Options 2 and 3, this option monitors room air temperatures and adjusts the setpoint with the BAS. The BAS can read an analog room temperature signal from a sensor installed in each diffuser and can read and reset the room temperature setpoint of each diffuser using analog signals from an Acutherm Wall Adjuster.

Option 5: Combination of Therma-Fuser™ stand alone diffusers with Therma-Fuser™ DDC interoperable diffusers

This option offers complete BAS digital input and output on selected diffusers and the simplicity of no wiring to the others. Key spaces are monitored and controlled by the BAS. Other spaces have the benefit of simplicity and low installation cost due to no diffuser wiring.

Option 6: Therma-Fuser™ DDC Interoperable diffusersThis option offers complete BAS digital input and output.

Each diffuser has the ability to supply room temperature, airflow and supply air temperature and receive signals for room temperature setpoint, minimum airflow setpoint, maximum airflow setpoint, override open, override closed, CO2 override and more. Digital signals can be either BACnet or LonWorks.

Take a look at the complete design guide: Acutherm BAS Design Guide

Have more questions, askRick?

result, sound attenuation components can be smaller, and in some cases can be eliminated. Smaller sound attenuators decrease the degree of static pressure drops. Savings are in both initial installation cost and in improved system efficiency

result, sound attenuation components can be smaller, and in some cases can be eliminated. Smaller sound attenuators decrease the degree of static pressure drops. Savings are in both initial installation cost and in improved system efficiency

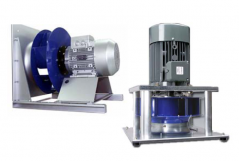

Custom Air Handling Units (AHU’s)

Custom Air Handling Units (AHU’s)  Custom AHU’s have a longer useful life, require less energy, and are more reliable and serviceable. In 24/7 applications we have seen simple paybacks around 2-5 years when compared to conventional AHU’s.

Custom AHU’s have a longer useful life, require less energy, and are more reliable and serviceable. In 24/7 applications we have seen simple paybacks around 2-5 years when compared to conventional AHU’s.

A. We have done a significant number of laboratory fume hood exhaust systems using

A. We have done a significant number of laboratory fume hood exhaust systems using

Constraints:

Constraints:

All the piping was factory installed and insulated. This reduced the amount of field labor required to install the unit. It also limited the amount of time to cut over the new unit and integrate it into the existing systems. The piping was fully coordinated at the factory to maximize service space within the corridor.

All the piping was factory installed and insulated. This reduced the amount of field labor required to install the unit. It also limited the amount of time to cut over the new unit and integrate it into the existing systems. The piping was fully coordinated at the factory to maximize service space within the corridor.

Q. Should I use a bypass damper on an Energy Recovery Wheel?

Q. Should I use a bypass damper on an Energy Recovery Wheel?